Energy modeling for production processes

Competences:

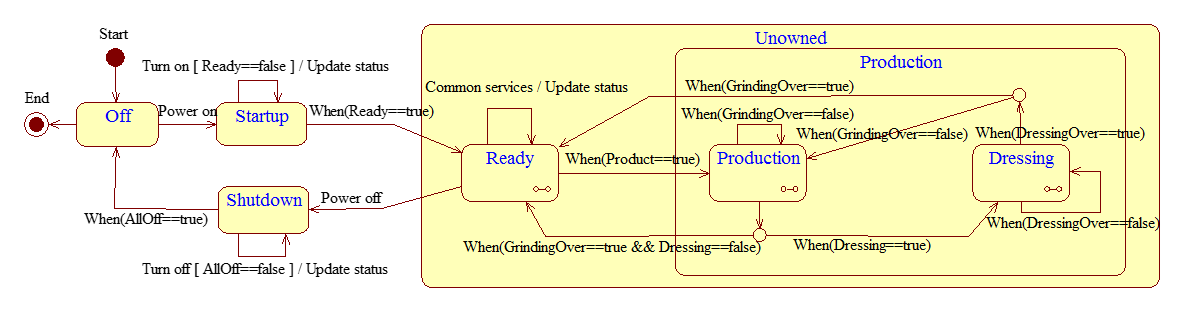

- Energy model based on finite state machines

- Power profile identification based on measured data

- Energy consumption simulation on multiple factory levels: single machine, single line, multiple lines, and multiple factories

Research projects:

- iMinds Sencom: Companies today already have a lot of monitoring and control capabilities in their production processes. This is the job of the Manufacturing Execution System (MES). However, a MES does not yet take into account energy consumption values. Energy consumption is nonetheless vital for producers implementing energy-intensive processes. SENCOM aims to add that extra dimension and develop a new, energy-efficient scheduling technology.

- iMinds Forward: The FORWARD project investigated how white spots (i.e. areas that lack wireless coverage) and sources of network interference in industrial settings can be predicted more quickly – using that knowledge to automatically initiate on-the-fly network (re)configurations. Objective: to provide optimal network coverage and support a quick hand-over of traffic between (Wi-Fi) access points at all times – in any warehouse or production facility.

Key Publications: